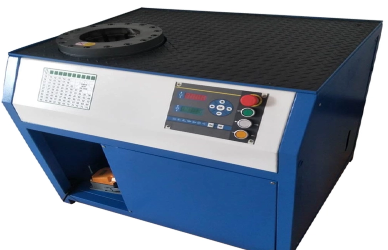

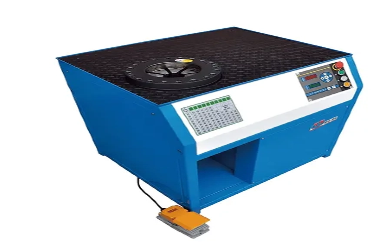

Nut crimping machines are highly versatile tools designed to securely attach connectors to hoses, wires, and other components, ensuring reliable, leak-proof connections. One of the key advantages of these machines is their ability to work with different hose fittings, making them suitable for a wide range of applications across industries such as automotive, hydraulics, and aerospace. The ability to adjust crimping force and die size allows these machines to accommodate various fitting sizes and materials, ensuring optimal performance. Whether for low-pressure systems or high-pressure fluid transfer, nut crimping machines are essential for creating durable, safe connections that can withstand harsh operational conditions. Understanding how to select the correct settings for different fittings is crucial for achieving high-quality, reliable crimps.

Understanding Nut Crimping Machines

A nut crimping machine is a specialized tool used to secure connectors (such as nuts or fittings) onto hoses, wires, and other components. The crimping process involves applying mechanical force to ensure a tight, secure connection, which is essential for creating reliable and leak-proof joints in various systems.

1. How Nut Crimping Machines Work

Nut crimping machines operate by positioning the connector and hose or wire into a die within the machine. When the machine is activated, it applies precise pressure to the connector, compressing it tightly around the material. The amount of force used ensures that the fitting is properly secured, forming a strong, durable bond that holds the components together under stress.

2. Role in Creating Reliable Connections

Nut crimping machines play a crucial role in forming leak-proof connections. In industries such as hydraulics, pneumatics, automotive, and electrical, where fluid transfer, signal transmission, and power distribution are critical, these machines ensure that the connections are both strong and secure. The crimping process creates a seal that prevents leaks, which is vital for maintaining the safety and efficiency of fluid and power systems.

3. Importance in Fluid and Power Systems

In fluid and power systems, the connections must withstand high pressures, vibrations, and temperature changes. Nut crimping machines help ensure that the crimped connections are durable and able to handle these harsh conditions. This is particularly important in systems like hydraulic systems, where a failure in the connection could lead to leaks, inefficiencies, or safety hazards.

4. Conclusion

In summary, nut crimping machines are essential tools for creating reliable, secure, and leak-proof connections in fluid and power systems. Their ability to provide consistent, high-quality crimps ensures the safety and efficiency of systems that rely on secure fittings for optimal performance.

Compatibility with Different Hose Fittings

Nut crimping machines are highly versatile tools that can be used with a wide range of hose fittings, such as those made from brass, steel, aluminum, and other materials. This versatility makes them essential for industries that require secure, durable connections across various applications, including hydraulic, pneumatic, and automotive systems.

1. Range of Hose Fittings

Nut crimping machines are compatible with different types of hose fittings, including brass, steel, aluminum, and plastic fittings. Each material has its own set of characteristics, such as strength, corrosion resistance, and weight, which determine how the fittings should be crimped. For example:

Brass fittings are often used in low-pressure systems and are softer, requiring less crimping force.

Steel fittings are more durable and are commonly used in high-pressure systems, requiring higher crimping force and more precise control.

Aluminum fittings are lightweight and corrosion-resistant but may require specific dies and pressure to ensure a secure connection.

2. Adjustments for Crimping Force and Die Size

To work effectively with these varying materials, nut crimping machines offer adjustable crimping force and die sizes:

Crimping Force: The required crimping force depends on the material and the size of the fitting. Softer materials like brass need less force, while harder materials like steel require more pressure to achieve a secure, leak-proof connection. Adjusting the crimping force ensures that the connector is tightly secured without damaging the material.

Die Size: The die size must match the diameter and thickness of the connector and hose to ensure proper compression. Different fittings require different die sizes to achieve uniform crimping. For instance, a larger die is needed for larger diameter hoses or fittings, while a smaller die is used for finer connections.

3. Importance of Proper Adjustments

By adjusting the crimping force and die size, nut crimping machines can accommodate various fittings and materials, ensuring uniform compression and consistent results. These adjustments are crucial for maintaining reliable, leak-proof connections, regardless of the fitting type or material used. Proper adjustments help prevent issues such as loose fittings, damaged components, or inefficient seals, ensuring the integrity of the entire system.

Factors Affecting Compatibility

When using a nut crimping machine, several factors determine compatibility and ensure secure, durable connections. These include fitting size, material type, and application requirements.

1. Fitting Size

The diameter and thickness of the hose fittings directly influence the required diesize and crimping force:

Diameter: Larger fittings need larger dies for sufficient compression, while smaller fittings require smaller dies for precision.

Thickness: Thicker materials like metal fittings need more crimping force to achieve a secure crimp, while thinner materials, such as rubber, require less force.

Matching the correct die size and crimping force ensures a tight, reliable connection.

2. Material Type

Different materials require different settings:

Rubber and plastic fittings need moderate to low crimping force and specific die sizes to prevent damage.

Metal fittings (such as brass, steel, or aluminum) require higher crimping force due to their rigidity and durability.

Adjusting the crimping force and die size based on the material ensures effective crimping without damaging components.

3. Application Requirements

Whether the fitting is used in low or high-pressure systems affects the crimping process:

Low-pressure systems may require standard crimping force and dies.

High-pressure systems need higher crimping force and stronger dies to ensure leak-proof, durable connections.

Benefits of Versatility

Nut crimping machines are highly versatile, offering significant benefits such as cost-effectiveness and efficiency when used for different fitting types.

1. Cost-Effectiveness

Using one machine for multiple fitting types reduces the need for investing in specialized equipment, cutting down both initial costs and maintenance expenses. A single machine can handle various materials, such as brass, steel, and aluminum, consolidating operations and lowering overall equipment costs.

2. Efficiency

A versatile crimping machine increases production efficiency by adapting quickly to different fittings, hose types, and materials. This flexibility reduces setup times and downtime, leading to smoother workflows and faster production cycles.

3. Reduces Need for Specialized Equipment

Instead of needing multiple machines for different tasks, a versatile crimping machine handles a variety of fitting types, saving time and resources by eliminating the need for specialized tools.

4. Space and Resource Savings

By reducing the number of machines, companies save on factory space and storage. Fewer machines also simplify maintenance and staff training, leading to more streamlined operations.

FAQ

1.Can a nut crimping machine work with all types of hose materials?

Yes, nut crimping machines are designed to handle various hose materials, such as rubber, plastic, and metal, as long as the appropriate crimping force and die size are selected based on the material’s characteristics. Each material may require different settings to ensure secure, reliable crimps that meet performance requirements.

2.Do I need to change dies for different hose fittings?

Yes, the die size may need to be adjusted depending on the fitting size and material. For consistent, reliable crimping, it is important to use the correct die that matches the dimensions and type of fitting to ensure uniform compression and a tight, secure connection.

3.How do I determine the correct crimping force for different hose fittings?

The correct crimping force depends on the material type and the diameter of the hose fitting. Softer materials, like rubber or plastic, generally require less force, while harder materials like metal need more pressure to achieve a secure crimp. Always refer to the manufacturer’s guidelines for optimal force settings to avoid under- or over-crimping.

4.Can a single nut crimping machine handle multiple fitting sizes?

Yes, a single nut crimping machine can handle multiple fitting sizes. With adjustable dies and crimping force settings, the machine can be easily configured to work with a variety of hose fittings and sizes, making it a versatile tool for different applications. This flexibility helps businesses save time and resources while ensuring reliable connections across various fitting types.

Conclusion

Nut crimping machines are incredibly versatile, designed to handle a wide variety of hose fittings for numerous applications, such as automotive, hydraulics, pneumatics, and electrical systems. They can efficiently work with different materials like rubber, plastic, and metal, as well as a range of fitting sizes, making them essential tools in industries requiring secure, durable, and reliable connections. To achieve the best performance, it's crucial to use adjustable nut crimping machines that allow for precise crimping force and die size adjustments. This ensures compatibility with various fitting types, materials, and sizes, ultimately leading to optimal results in creating strong, leak-proof connections. By utilizing these adaptable machines, businesses can streamline their operations, enhance efficiency, and ensure consistent, high-quality crimping across a range of applications.