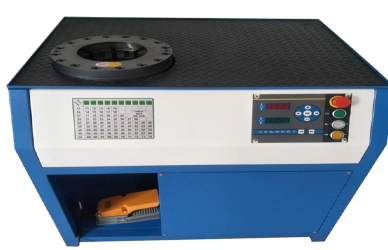

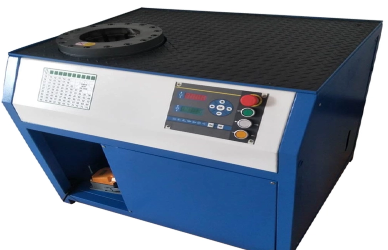

When using a nut crimping machine, selecting the right crimping force and die size is crucial for ensuring the quality and reliability of the crimped connections. The crimping force must be applied precisely to securely attach the connector to the wire or hose without causing damage, while the die size must match the dimensions of the connector to achieve uniform compression. Incorrect crimping force or die size can lead to weak or inconsistent connections, which may result in failures under stress, such as leakage, electrical failure, or system malfunctions. By choosing the appropriate force and die size, manufacturers can ensure that the crimped connections are strong, durable, and able to withstand pressure, vibration, and other harsh conditions. This is essential for maintaining the performance, safety, and reliability of the systems in which these connections are used.

Understanding Crimping Force

Crimping force refers to the amount of mechanical pressure applied by a nut crimping machine to compress a connector (such as a nut or fitting) onto a hose, wire, or other components. This force is a critical part of the crimping process, as it ensures the connector forms a tight, secure bond with the material, creating a reliable connection that can withstand the stresses of operation, such as pressure, vibration, and temperature fluctuations.

1.Crimping Force and Material Type

The amount of crimping force required depends largely on the material type being crimped:

Wires: For electrical connections, the force must be enough to compress the connector around the wire to create a low-resistance electrical connection, without damaging the wire's insulation or causing the wire to break.

Hoses: For hydraulic or pneumatic applications, crimping force must be sufficient to compress the fitting around the hose, creating a leak-proof seal. Too little force could result in a weak joint, while too much force could crush or damage the hose.

Fittings: The connector or fitting itself may require different forces based on the material (e.g., brass, aluminum, steel). Softer materials like aluminum require less crimping force compared to harder materials like steel, where more pressure is needed to create a secure connection.

2.Insufficient vs. Excessive Crimping Force

Both insufficient and excessive crimping force can result in poor-quality connections:

Insufficient Crimping Force: If the crimping force is too low, the fitting may not securely grip the material. This can lead to loose fittings, which are prone to leaks, electrical failure, or disconnection under stress. In hydraulic applications, this can cause fluid leakage and system inefficiencies.

Excessive Crimping Force: On the other hand, if the force is too high, it can damage the material. For wires, too much force can cause the conductor to break, and for hoses, it can crush or distort the inner lining, weakening the connection and compromising the system's integrity.

Choosing the Right Die Size

Die size refers to the dimensions of the crimping die used in a nut crimping machine to compress a connector onto a wire, hose, or fitting. The die plays a crucial role in shaping and securing the connection, ensuring that the connector is tightly and evenly attached to the material. Using the correct die size ensures that the crimp is uniform, precise, and reliable, which is critical for maintaining the performance and safety of the system.

1.How Diameter and Thickness Affect Die Size

The required die size is determined by the diameter and thickness of both the connector and the wire or hose:

Connector Size: The size of the connector (such as a nut or fitting) dictates the opening of the die. A connector that is too large or too small for the die will not be crimped properly, leading to weak or ineffective connections.

Wire or Hose Size: The diameter and thickness of the wire or hose also influence the required die size. A thicker wire or hose requires a larger die to ensure sufficient compression, while a thinner wire or hose will require a smaller die to achieve the correct level of force and secure connection.

The die must be selected to match the exact size of the connector and the material being crimped to ensure that the compression is even and precise.

2.Importance of Correct Die Size

Using the correct die size is essential for achieving uniform compression and consistent results. If the die size is not matched correctly to the connector and material:

Under-compression: If the die is too large, it may not compress the connector tightly enough, resulting in a loose fitting that could lead to leaks, electrical failures, or system malfunctions.

Over-compression: If the die is too small, it may apply too much pressure to the connector, which can damage the wire, hose, or connector, compromising the connection's integrity.

Using the correct die size ensures that the crimping process achieves consistent, reliable connections that are strong, durable, and able to withstand the operational stresses placed on them, such as pressure, vibration, and temperature changes. It is essential for maintaining the performance and safety of the systems where these connections are used.

Factors to Consider When Selecting Crimping Force and Die Size

Selecting the right crimping force and die size for a nut crimping machine is essential for creating secure, reliable connections. The following factors should be considered:

1. Material Type

Different materials require varying crimping forces and die sizes:

Wires: Softer materials like copper need less crimping force than harder materials like steel.

Hoses: Hydraulic hoses may need more force and a larger die for a tight seal.

Connectors: Harder materials require higher crimping force for secure connections.

Matching the crimping force and die size to the material ensures optimal results without damage.

2. Connector and Wire Size

The size of the connector and wire or hose directly impacts the selection:

Larger components require a larger die, while smaller components need a smaller die to achieve proper compression.

Compatibility between the connector and wire size ensures uniform and secure crimping.

3. Application Requirements

Consider the operating conditions:

High Pressure: Crimping force must be sufficient to withstand high-pressure systems.

Vibration: Increased crimping force may be needed for applications exposed to vibration.

Extreme Temperatures: Proper crimping ensures the connection remains secure under temperature variations.

4. Machine Specifications

Choose a machine with adjustable crimping force and die sizes to handle various materials and applications. Machines with versatile dies and adjustable force provide flexibility for different tasks.

Testing and Calibration

Testing and calibrating a nut crimping machine is crucial to ensure that the correct crimping force and die size are being applied consistently. Proper calibration guarantees that the machine delivers precise, uniform crimps, which are essential for creating strong, reliable connections. Without proper testing, there is a risk of applying too much or too little force, which can lead to weak or damaged connections.

1.Importance of Testing and Calibration

Accuracy: Regular calibration ensures the crimping machine operates within the required specifications, preventing errors that could affect the quality of the crimped connections.

Consistency: Calibration helps maintain uniform crimping force across all components, ensuring that each connection is secure and durable.

Quality Control: Proper calibration minimizes the risk of faulty crimps that could lead to product failures, particularly in high-stress environments like automotive, aerospace, or hydraulic systems.

2.Test Crimps and Inspection

Before transitioning to full-scale production, it is essential to perform test crimps using the selected die size and crimping force. Inspecting the quality of these test crimps helps verify that the compression is even, the connector is securely attached, and the connection meets the necessary strength and reliability standards.

Visual Inspection: Check for any visible signs of damage or improper crimping, such as loose fittings or crushed materials.

Pull Test: Perform a pull test to ensure the crimped connection can withstand the required mechanical load.

Leak Test: For hydraulic or fluid systems, perform a leak test to ensure that the crimped connection is leak-proof.

FAQ

1. How do I know if my crimping force is too low or too high?

If the force is too low, the crimp will be loose and may cause a weak connection. If the force is too high, it can damage the wire or connector, affecting performance.

2. Can I use the same die size for different types of connectors?

No, different connectors require different die sizes based on their diameter and thickness. Always use the die that matches the connector size for uniform crimping.

3. How does crimping force affect the reliability of the connection?

Correct crimping force ensures a tight, secure connection that withstands pressure and vibrations. Too much or too little force can result in unreliable connections.

4. Can crimping force be adjusted on all machines?

Not all crimping machines offer adjustable crimping force. However, many modern machines, especially hydraulic and electronic models, allow adjustments for better flexibility in various applications.

Conclusion

Selecting the right crimping force and die size is essential for ensuring secure, durable connections that can withstand the demands of various applications. Proper crimping force ensures that the connector is tightly and evenly secured, while the correct die size ensures consistent compression, preventing weak or faulty connections. To achieve optimal crimp quality, it is crucial to regularly calibrate and test the crimping machine. This helps ensure that the correct settings are applied consistently, allowing for reliable, high-quality crimps that meet safety and performance standards. By incorporating regular testing and calibration, manufacturers can enhance quality control and ensure that every crimped connection is strong, secure, and capable of performing under pressure.